What is the best edgework for glass shelves?

The average homeowner buys glass very rarely and is therefore not aware of the types of glass, the choices of edge finishes that are available, and the pricing structure of polished glass. This post will give you insider info on the mysteries of glass edgework.

By far the best edgework for glass shelving is flat polished but there are several money-saving strategies that the frugal shopper should know about. Read this post for insider glass company information which will teach you about edgework and help you to become an educated and economical shopper.

Saving shoppers can save money on glass and mirror by learning “glass speak”. Follow this link to learn how to sound like a glass insider and score big savings!https://artistry-in-glass.com/how-to-save-money-when-buying-glass-mirror/

What is “Edgework” in the glass industry?

When glass is cut with a glass cutter, the edge is razor-sharp and dangerous to handle. The process of grinding and polishing to make the glass edges safe and/or decorative is called edgework. This post describes the common types of glass edgework and recommends the best choices for shelves, Edgework is one of the processes (including hole drilling and notching) which are grouped under the general term – fabrication in the glass business.

The most popular choices of edgework for shelving are:-

SEAMED

The least expensive option, seamed glass is clean-cut glass with the sharp edges sanded to make them safe to handle

FLAT POLISHED

The best option for shelves, flat-polished glass has perfect, machine-polished sides with 45 degree chamfers (arrisses)

PENCIL POLISHED

Attractive modern look and just as functional as flat polished but some glass retailers charge a premium for pencil polishing

Why do I need to pay the glass company for edgework?

Glass without edgework is called “clean-cut” and on the side scored by the diamond or carbide cutter, has fine micro-chips which can develop into fractures when the shelf is loaded. The opposite side is also dangerous because it is razor-sharp and can produce conchoidal (shell-like) fractures if chipped.

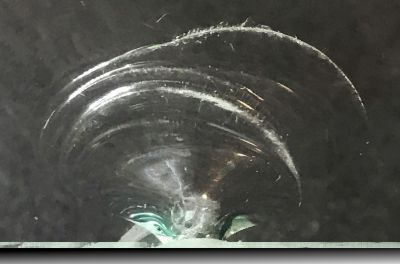

Close-up of conchoidal fracture in glass

The sharp edges of clean-cut glass can very easily be chipped into distinctive conchoidal (shell-like) fractures. This fracture pattern is characteristic of brittle isotropic materials and is well known from stone-age tools formed by the skilled process of flint-knapping. The simple procedure of sanding off the razor-sharp edge (seaming) prevents the formation of conchoidal fractures.

Never be tempted to economize with “Clean-Cut” glass

Clean-cut glass is dangerous and can easily fracture – with potentially disastrous consequences for your family and property. Seaming and/or polishing removes the micro-chips and make the glass much less likely to break and much less likely to form conchoidal chips.

Can I do my own edgework?

Flat polished edges – no but seamed edges – yes.

Flat polishing is done on large expensive machines in glass factories (see the animated image below) and is outside the scope of homeowners but seamed edges are possible: follow these instructions:-

How to make a seamed edge on glass

Seaming is the process of sanding down the sharp and micro-fractured edges on clean-cut glass. Using 320 or 400 grit wet dry sandpaper or emery cloth on a sanding block, carefully swipe the sharp edges of the glass. Make sure to spray the sandpaper with water to prevent the possibility of inhaling dangerous silica dust, and wear goggle and gloves for safety.

Flat Polished Edges – Useful Information

Flat Polished edges are made on expensive, hi-tech machines in the glass factory. A clean-cut sheet of glass is fed automatically over a series of progressively finer, water-cooled grinding and polishing wheels to produce a perfect machine polish with 45 degree arrisses. (Note that this is an animated gif – in reality, the glass moves slowly and only goes through the machine one time!).

Examples of defective polishing

Examine your polished edges closely when you pick up your glass. The flat polish should be perfect. The examples shown here are the result of badly calibrated grinding wheels which have left coarse and fine striations on the edge. Ask the glass retailer to re-make the shelves.

Pencil polished edges

Pencil polishing is commonly found on shelves in imported or mass-produced furniture. If you need to replace a broken shelf and match the pencil polishing – ask your glass professional for advice. Some glass retailers charge the same price for pencil and flat polishing of 1/4″ glass but most charge more for pencil edges. In my experience, all glass factories will charge more for pencil polishing of “heavy” glass – 3/8″ and 1/2″ thick.

I have an old piece of glass – can you cut it and polish the edges for me?

A friendly and helpful local glass company may go the extra mile by cutting and seaming a piece of glass for a special customer. However, it is almost never economical to send an old piece of glass all the way back to the factory in order to make a machine polished or beveled edge.

The Cost of Seaming and Polishing Glass

Edgework (seaming, polishing and beveling) is priced by a formula based on the cost per linear inch of the edge to be processed. Examples of typical retail prices are shown for clear annealed (ie not tempered) glass in a variety of shelf sizes and thickness

| Shelf size in inches | Cost 1/4″ thick seamed edge | Cost 1/4″ flat polished edge | Cost 3/8″ flat polished edge | Cost 1/2″ flat polished edge |

|---|---|---|---|---|

| 18 * 6 | $22.00 | $30,00 | $68.00 | $85.00 |

| 24 * 6 | $25.00 | $32.00 | $73.00 | $90.00 |

| 36 * 8 | $28.00 | $40.00 | $94.00 | $115.00 |

| 48 * 8 | $36.00 | $52.00 | $110.00 | $147.00 |

These are guideline costs for clear annealed (ie not tempered) glass shelves with seamed and flat-polished edges . They vary widely across the USA, being most expensive in up-market urban areas and in isolated locations (Hawaii & Alaska). Note that seaming is not really an option with heavy (3/8″ & 1/2″) glass unless the seamed edges will be completely concealed (for example by wood trim). If you need standard sizes, imported tempered shelves are less expensive – these will be evaluated in future posts.

If the back of the shelf will not be visible, ask your glass retailer to save you money by having only the front edge of the glass polished. Seaming the back edge (and even the sides) will reduce the cost of the shelf. Note that heavy glass (3/8″ & thicker) really needs to be polished rather than seamed.

I ordered my shelf 1/4″ too wide – can you cut it down for me?

Triple-check your measurements – using a second tape to be sure

It is not possible to cut 1/4″ or less from 1/4″ thick or thicker glass and it is far too labor-intensive to grind the glass down to the exact size. So be sure to order the correct size (allow “wiggle-room” if in doubt.)

I’d like my shelf to have a nice beveled edge …

Many customers request a “beveled edge” in the mistaken impression that beveled means smoothed or chamfered. In the glass business, the term bevel is used specifically for the 1/2″ to 1 1/2″ wide faceted border which is used on tabletops or around the edges of decorative mirrors. Beveling more or less doubles the cost of a finished sheet of glass and is almost never a good choice for shelving – it is unnecessary, it tends to distract from the contents of the shelf and it is much more expensive than flat polishing.

Conclusions & Recommendations

- The best all-around edgework for glass display shelves is flat polished

- Expensive beveled glass is not necessary or recommended for shelving

- Consider economizing by seaming edges that will not show

- Never use clean-cut glass – it is likely to fail with catastrophic results

- Measure with great care – it is very labor-intensive and expensive to grind glass

- Glass companies will generally not polish or bevel your old glass

- See this post for information on tempered glass

Glass tabletops & shelves – info from Artistry in Glass

- Benefits of glass shelving – info from experts!

- How much do glass tabletops cost?

- Do glass shelves need to be tempered?

- What is the best thickness for glass shelves?

- Best edge type for glass shelves, polished or beveled?

- How much weight can a wall shelf carry?

- What color glass should my shelves be?

- Glass tabletops – 10 amazing benefits explained

- How to order a glass tabletop

- Best thickness for glass tabletops – expert advice

- Should glass tabletops be tempered?

- Should glass tabletops be beveled?

- How to paint a glass tabletop

- All about tempering glass tabletops!

- How to tell if your glass is tempered

- Can tempered glass be cut?

- How to protect your wood table with glass

- How to fix a scratched glass tabletop

- How to fix a chipped glass tabletop

- How to replace broken patio table glass

- How to measure for a glass tabletop

- Video – how to measure your tabletop

- Plexiglass vs glass – pros and cons

- Beveled glass table base – a case study

- Choosing between tempered & laminated glass

- Glossary of terms used in the glass business